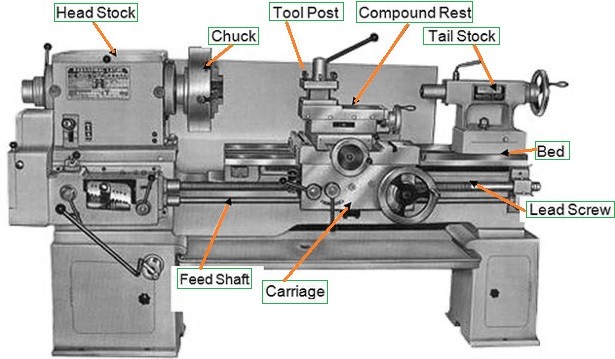

Lathe machines are indispensable in the machining industry due to their ability to shape, cut, and turn materials with precision. Understanding the essential lathe machine parts can significantly improve both your knowledge and efficiency in utilizing these powerful tools. This article will delve into the top 10 lathe machine parts you should be familiar with to maximize your machining capabilities.

1. Bed

The bed is the foundational component of a lathe machine, providing a stable base for all other parts. It is typically made from cast iron to ensure rigidity and minimize vibrations during operations. The bed supports the headstock, tailstock, and carriage, maintaining alignment and accuracy.

2. Headstock

The headstock is mounted on the left end of the lathe bed and houses the main spindle, speed control, and gears. It is responsible for holding and rotating the workpiece. The spindle’s speed and rotational direction can be adjusted to suit different machining operations.

3. Tailstock

Opposite the headstock, the tailstock supports the other end of the workpiece. It is particularly useful for long workpieces that need additional support to prevent deflection. The tailstock can be adjusted along the bed and can hold tools such as drill bits and reamers for added functionality.

4. Carriage

The carriage is the moving part that slides along the bed’s length. It holds the cutting tools and moves them into the workpiece. The carriage consists of several components, including the saddle, cross slide, and compound rest, which provide various degrees of movement and control.

5. Chuck

The chuck is a clamping device attached to the spindle that holds the workpiece securely in place. There are different types of chucks, such as three-jaw chucks for round workpieces and four-jaw chucks for irregular shapes. Some lathes also use collets or faceplates for specific applications.

6. Tool Post

The tool post is mounted on the carriage and holds the cutting tools. It allows for quick tool changes and adjustments during machining. Modern lathes often feature a quick-change tool post, which enhances productivity by reducing downtime between tool swaps.

7. Lead Screw

The lead screw is a long threaded rod situated parallel to the bed. It is driven by the headstock and is essential for thread cutting operations. The lead screw engages with the carriage, moving it in precise increments to produce accurate threads on the workpiece.

8. Feed Rod

Similar to the lead screw, the feed rod is used for general machining operations like turning and facing. It moves the carriage and cross slide automatically, ensuring consistent feed rates and smooth finishes on the workpiece.

9. Apron

The apron is attached to the front of the carriage and houses the mechanisms that control the movement of the carriage and cross slide. It includes the feed levers, clutches, and gears that facilitate both manual and automatic feed movements.

10. Compound Rest

The compound rest is mounted on top of the cross slide and allows for angular cuts. It can be swiveled to various angles, providing flexibility for precise tapering and contouring operations. The compound rest is particularly useful for intricate machining tasks requiring fine adjustments.

Conclusion

Understanding the key lathe machine parts is crucial for anyone involved in machining. Each component plays a vital role in the overall functionality and precision of the lathe machine. By familiarizing yourself with these parts, you can enhance your machining skills, improve efficiency, and ensure the longevity of your equipment. Whether you’re a seasoned machinist or a beginner, knowing your lathe machine parts will undoubtedly contribute to more successful and accurate machining projects.

Lathe machines are complex pieces of equipment, but with a solid grasp of their components, you can tackle a wide range of machining tasks with confidence. Keep this guide handy as a reference to the top 10 lathe machine parts, and you’ll be well on your way to mastering this essential tool in the machining industry.